Case

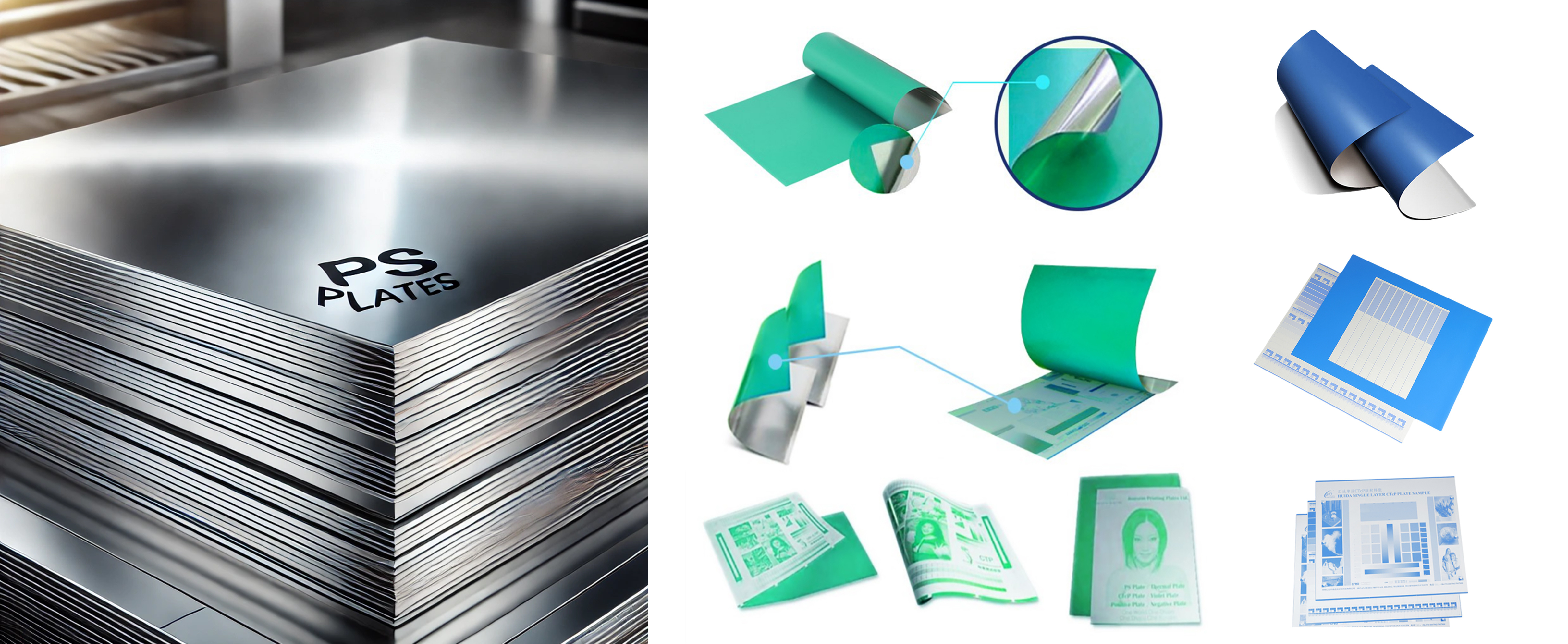

PS Plate/Board Project

Introduction Of The Project

With the rapid development of the printing industry, the demand for high-quality, high-performance printing plates continues to grow. The PS plate, with its unique advantages, has become a focal point within the industry. It offers excellent print quality and durability, meets environmental standards, is clean and hygienic, and is cost-effective. Its high resolution ensures clear text, fast printing speeds, and strong image reproduction capabilities. Additionally, the PS plate exhibits outstanding flatness, high strength, corrosion resistance, and excellent print adaptability, making it suitable for various complex printing processes.

Therefore, the PS plate project has a promising market outlook and tremendous growth potential.

The PS plate base is produced by hot and cold rolling processes, where aluminum alloy billets are rolled into thin sheets of specific thickness. After a specific surface treatment, the aluminum sheet is coated with a photosensitive resin, and once dried, it becomes suitable for various printing applications.

PS plate bases typically use 1050, 1060, or 1070 aluminum sheets, with aluminum content of ≥99.50%, ≥99.60%, and ≥99.70%, respectively.

They offer the following advantages:

- Low Density: Lightweight and easy to process and use.

- High Strength: Capable of withstanding the mechanical stress during printing.

- Moderate Wear Resistance: Suitable for multiple prints, with good durability.

- Good Formability: Easy to shape into the required plate materials.

- High Stability: The material maintains high dimensional and performance stability during use.

- Good Surface Treatment: Enhances the application of coatings and photosensitive resins, improving print quality.

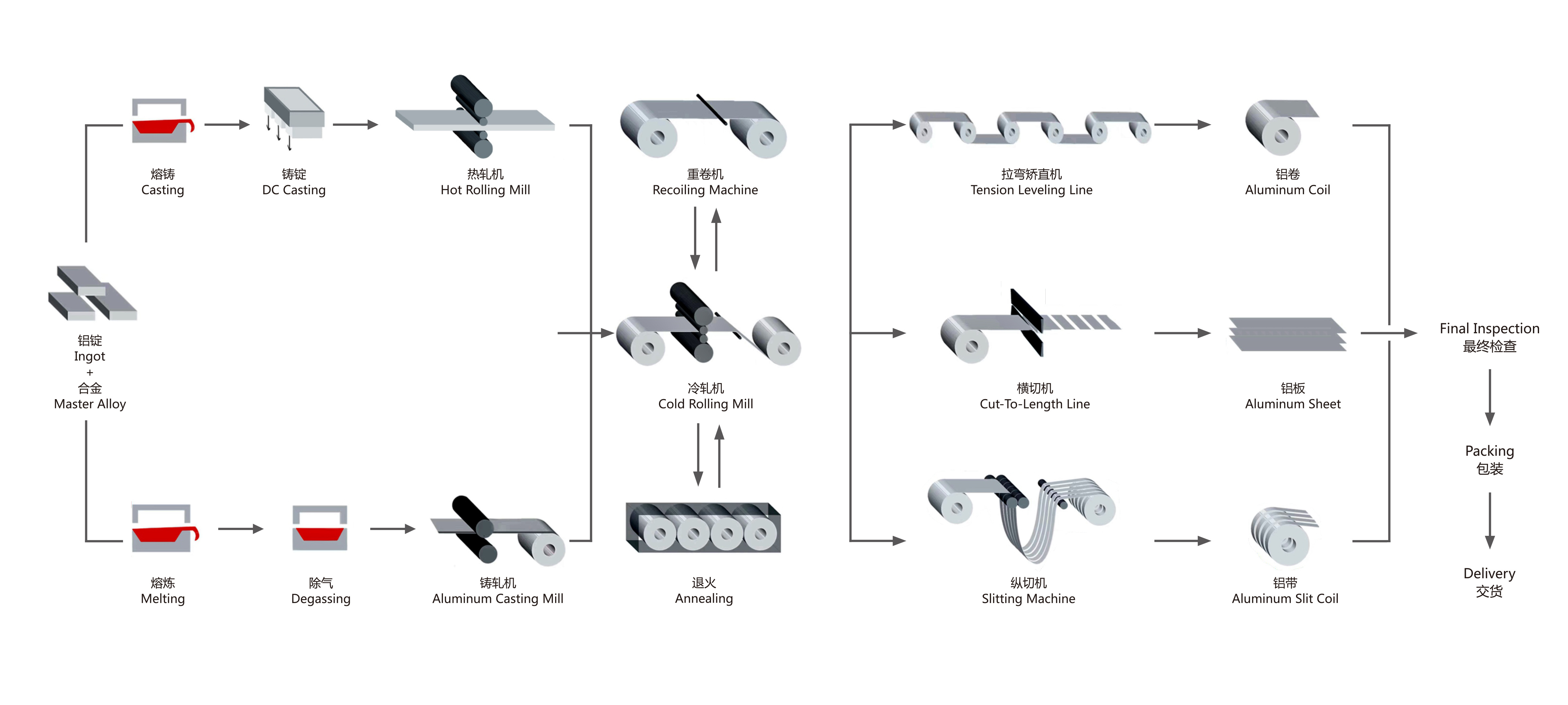

Processing Flow

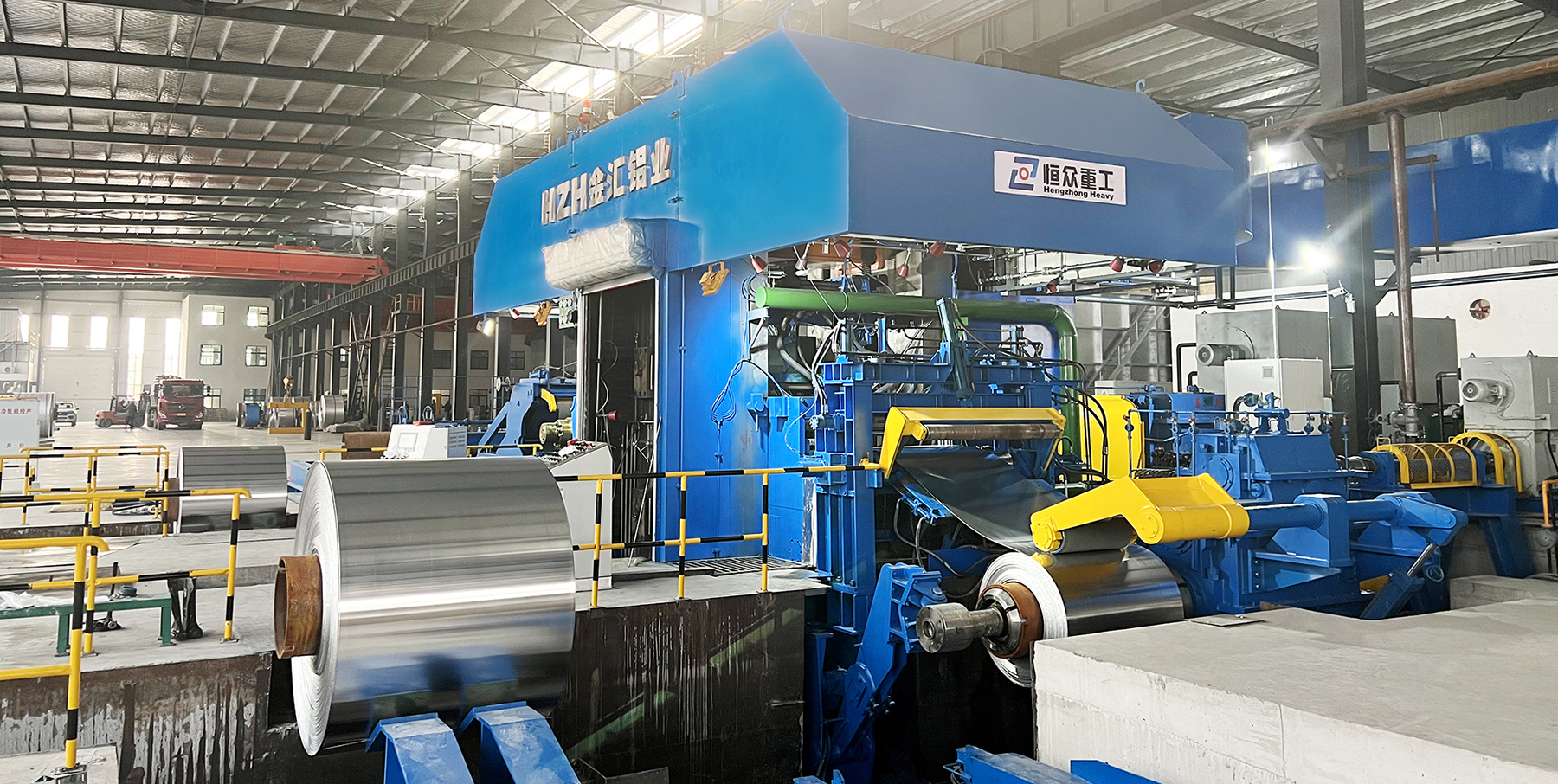

Main Equipment

1.Melting Furnace

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

2.Holding Furnace

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

3.Degassing Unit

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Insulation method: electrical heating

Power:90-150 KW

4.Casting Rolling Mill

Finished product thickness: 5.0-10mm

Finished product width: 800 -2200mm,Recommended models on demand

Rolling speed: 800 - 5000mm/min

5.Cold Rolling Mill

Finished product thickness: 0.1-4.0mm

Finished product width: 950 -2250mm,Recommended models on demand

Rolling speed: Max 1500m/min

6.Tension Leveling Line

Finished product thickness: 0.1-4.0mm

Finished product width: 600 -2350mm,Recommended models on demand

Rolling speed: Max 80 - 600m/min

7.Cut To Length Line

Finished product thickness: 0.12-2.0mm/1.0-5.0mm/3.0-8.0mm

Finished product width: 600 -2850mm,Recommended models on demand

Line speed: 20-60-100m /min