Case

Aluminum Foil Blank Project

The aluminum foil blank project plays a significant role in the aluminum processing industry, offering essential raw material for aluminum foil production. As industries like packaging, electronics, and home appliances rapidly expand, the demand for aluminum foil grows in parallel. This project ensures a stable supply of high-quality aluminum foil stock, meeting market needs while pushing the industry toward high-end, refined production.

By enhancing the quality and performance of aluminum foil stock, the project increases the value of aluminum foil products, boosting the competitiveness of aluminum processing companies. It also positively impacts related sectors, such as equipment manufacturing and logistics, fostering regional economic growth.

In addition, aluminum is highly recyclable. Through the aluminum foil stock project, the recycling of waste aluminum materials can reduce reliance on primary aluminum ores, thus lowering energy consumption and minimizing environmental pollution. By recycling and processing waste aluminum, the project supports a sustainable model of resource utilization, contributing to the circular economy.

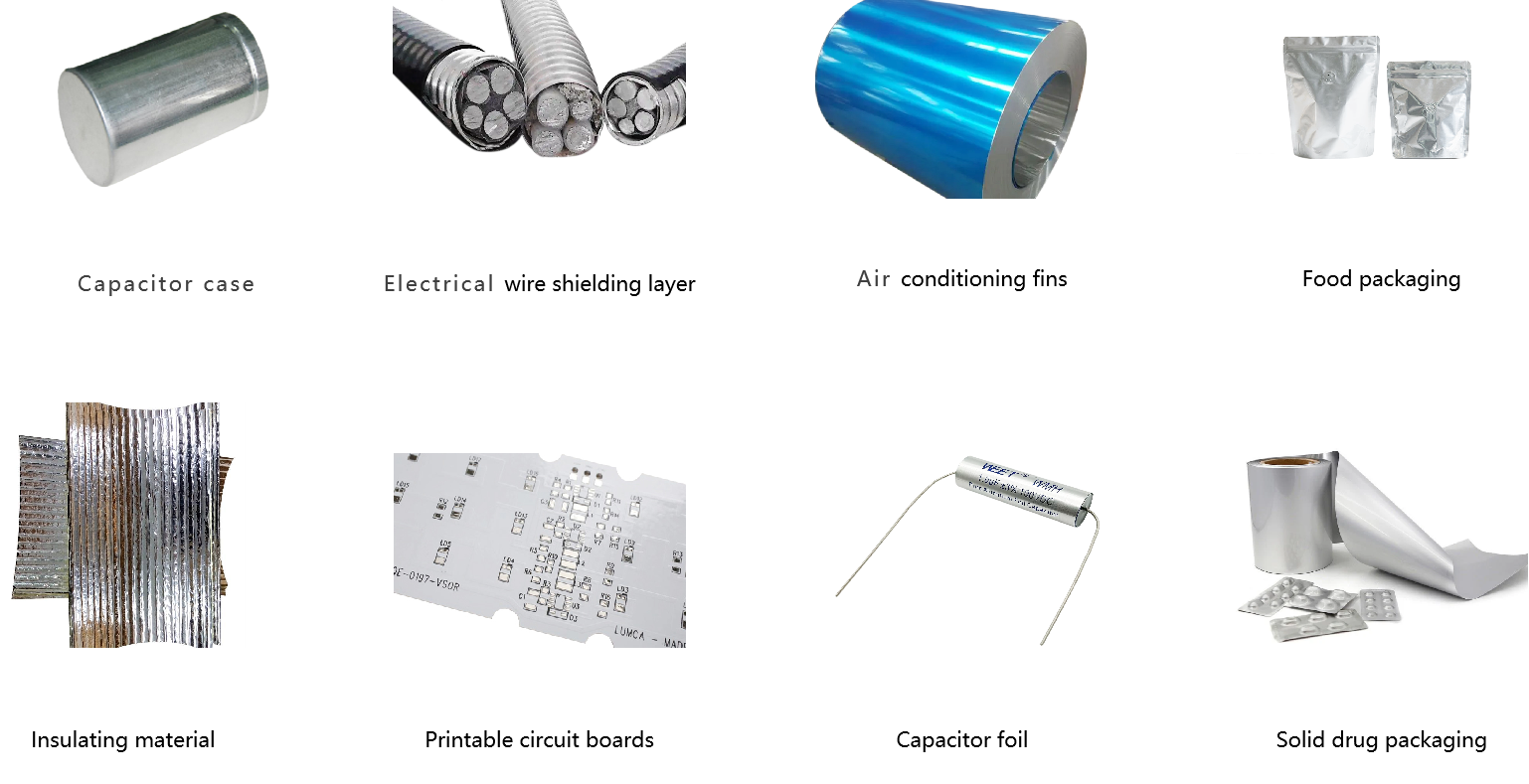

Product Structure

Range | Application | Typical use | Thickness | Advantage |

| 0.10mm-0.20mm | Electrical Industry Heat Exchangers Construction & Decoration | Electrical wire shielding layer Capacitor shell | 0.13mm 0.14mm | Good conductivity and mechanical strength |

| Air conditioning fins | 0.15mm | Increased heat exchange area, improved heat exchange efficiency | ||

| Exterior wall decoration Roofing panels | 0.15mm-0.20mm | High mechanical strength and durability | ||

| 0.05mm-0.10mm | Food Industry Industrial Sector | Food packaging | 0.06mm | Protects food from moisture, oxidation, and external odors |

| Insulating materials | 0.03mm-0.08mm | Reduces thermal transmission, lowers energy consumption | ||

| Automotive heat exchangers | 0.08mm | Good heat transfer efficiency and mechanical strength | ||

| 0.01mm-0.05mm | Electronics Industry Pharmaceutical Packaging | Capacitor foil | 0.01mm-0.03mm | High capacitance, low loss |

| Printable circuit boards | 0.015mm-0.03mm | Good electrical conductivity and processability | ||

| Solid drug packaging | 0.016mm-0.04mm | Effectively protects drugs from moisture, oxidation, and light degradation |

Aluminum foil products

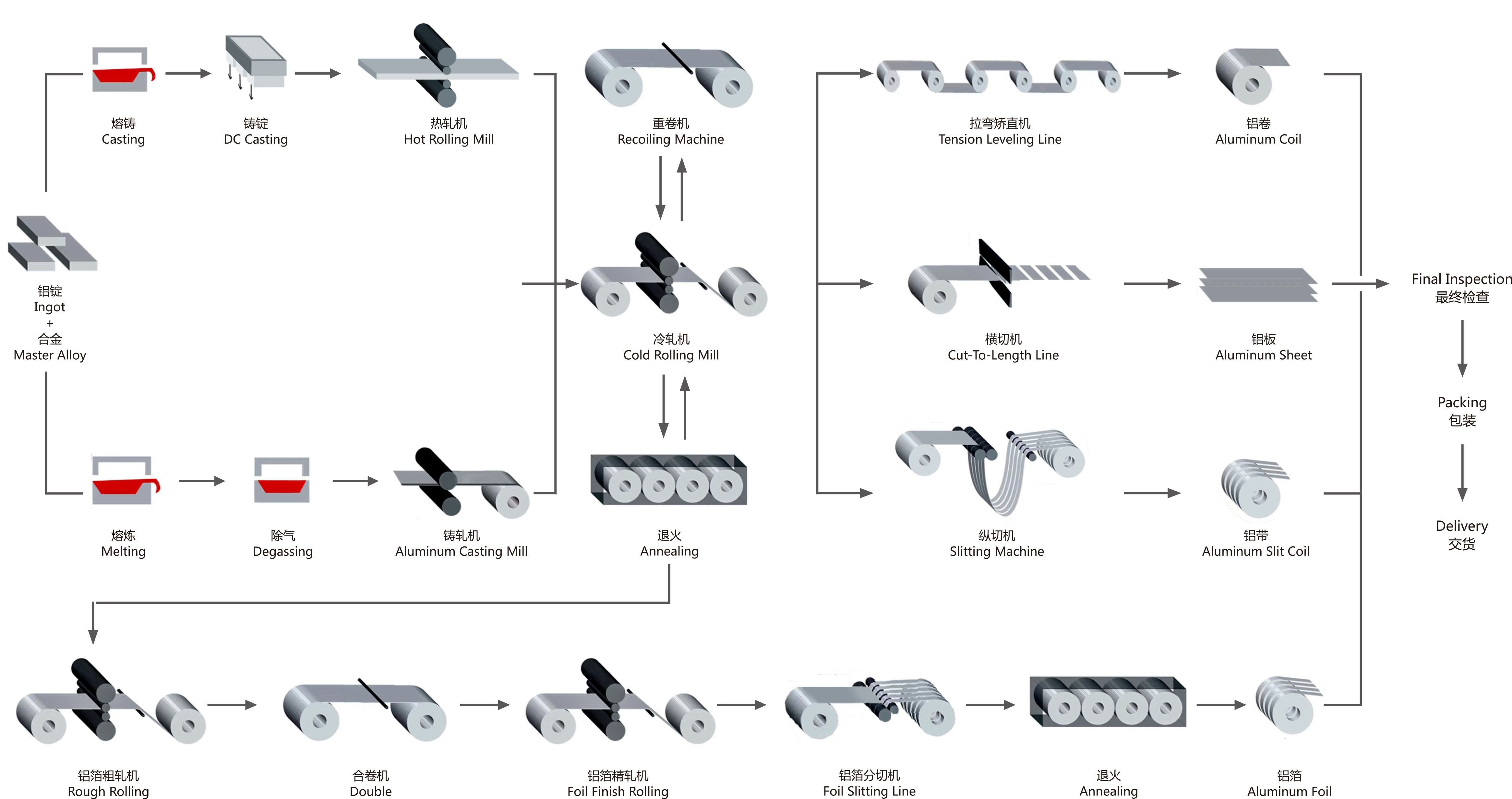

Process Flow

Equipment List

No. | Equipment |

1 | Melting furnace |

2 | Holding furnace |

3 | Continuous caster line |

4 | Charging car for the furnaces |

5 | Ceramic filter and Degasser |

6 | Electronic stirrer |

7 | Nitrogen making machine set |

8 | Water circuaton cooling system |

9 | Cold rolling mill |

10 | Coil annealing furnace |

11 | Loading car for annealing furnace |

12 | Tension leveling and cleaning line |

13 | Aluminium Foil Rough Rolling Mill |

14 | Aluminium Foil Finish Rolling Mill |

15 | AGC |

16 | AFC |

17 | Alminum Foil Annealing Funace |

18 | Foil Cutting/Slitting line |

19 | Heave gauge slitter |

20 | Cut to length line |

21 | Universal roll grinding machine |

22 | Roll grinding machine |

23 | Spare parts |

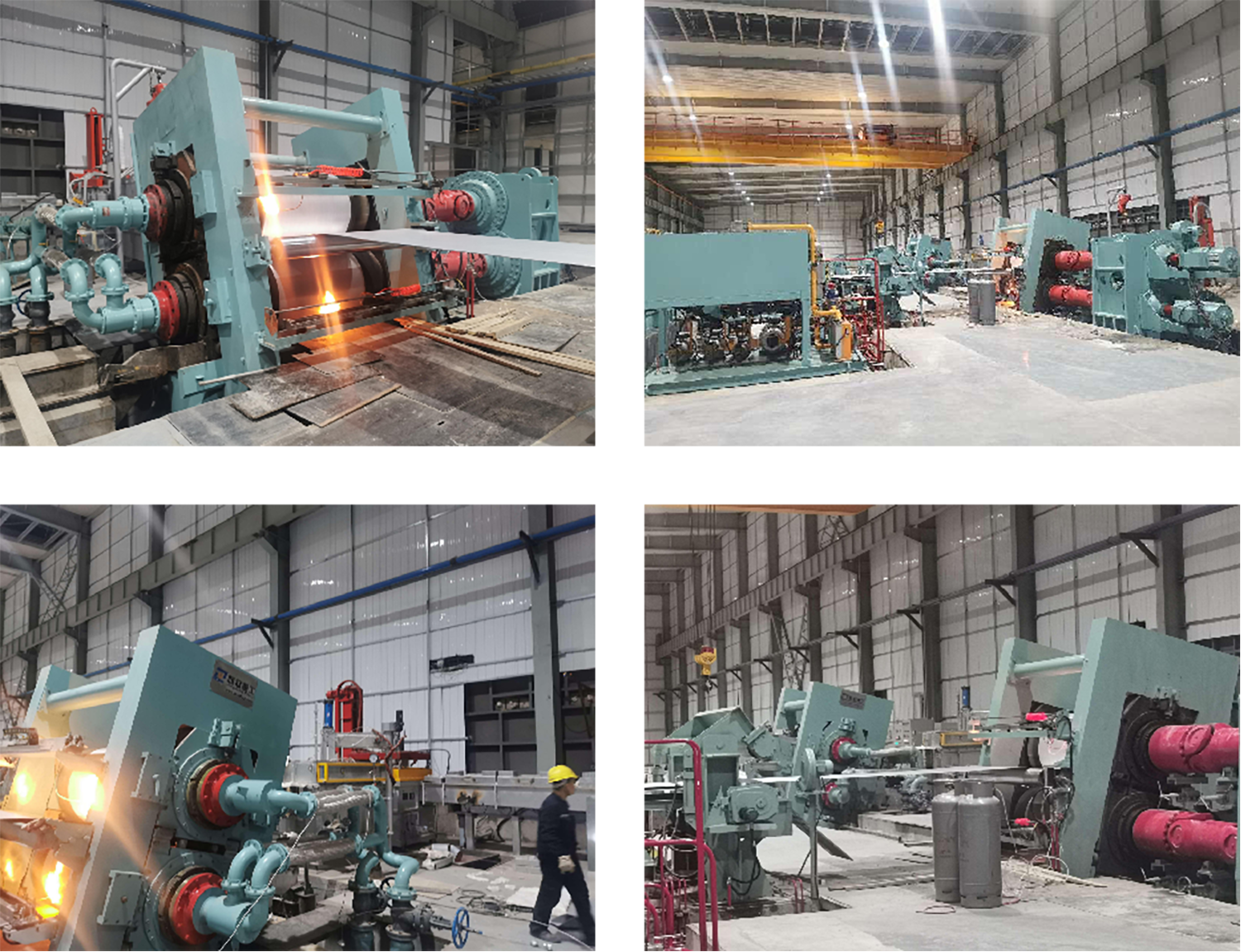

Customer Cases:

MINGTAI ALUMINUM INDUSTRY CO., LTD

Customer: Pars Aluman Kar Co.

Henan Mingtai Aluminium Industrial CO., LTD

Other Cases:

Henan Hengtong New Materials Co., Ltd

Guangxi Runtai Aluminum Co.,Ltd

Henan Xintai Aluminum Industry Co.,Ltd

Alukou Group