Case

Aluminum Curtain Wall Project

The application of aluminum plate in curtain wall panels has many advantages, providing more choices and possibilities for the design and construction of modern commercial buildings, public buildings and residential buildings. It has the advantages of beautiful appearance, superior performance, convenient construction, energy saving and environmental protection. With the continuous advancement and innovation of technology, the performance and quality of aluminum curtain walls will continue to improve, and their application in the construction field will also be more extensive.

Product Structure

The thickness of alu. plate | Characteristic | Application | Picture |

| 1.5-2.0mm | Easy to decorate, Small wind load | Interior partition、 Facade decoration of small buildings |  |

| 2.5-3.0mm | It can better withstand certain wind loads and deadweight | Commercial buildings、 Office Building |  |

| ≥3.5mm | Stronger deformation resistance and durability | Large public buildings、 High-rise buildings |  |

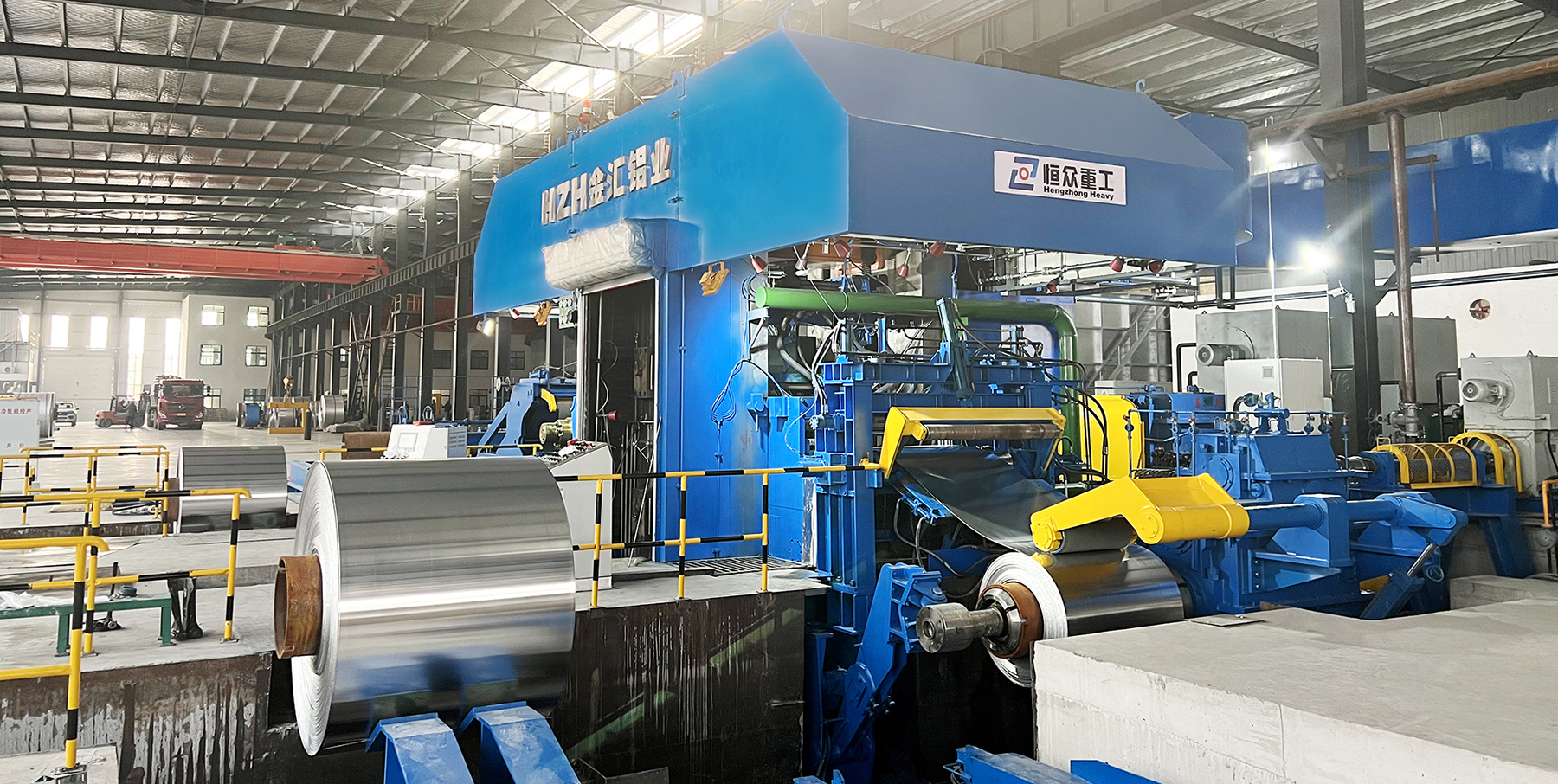

Equipment List

No. | Equipment |

1 | Melting furnace |

2 | Holding furnace |

3 | Continuous caster line |

4 | Charging car for the furnaces |

5 | Ceramic filter and Degasser |

6 | Electronic stirrer |

7 | Nitrogen making machine set |

8 | Water circuaton cooling system |

9 | Cold rolling mill |

10 | Annealing furnace |

11 | Loading car for annealing furnace |

12 | Tension leveling and cleaning line |

13 | AGC |

14 | AFC |

15 | Heave gauge slitter |

16 | Cut to length line |

17 | Universal roll grinding machine |

18 | Spare parts |

19 | Installation supervision and commissioning |

20 | Training |

21 | Production period |

22 | Factory area |

23 | Capacity |

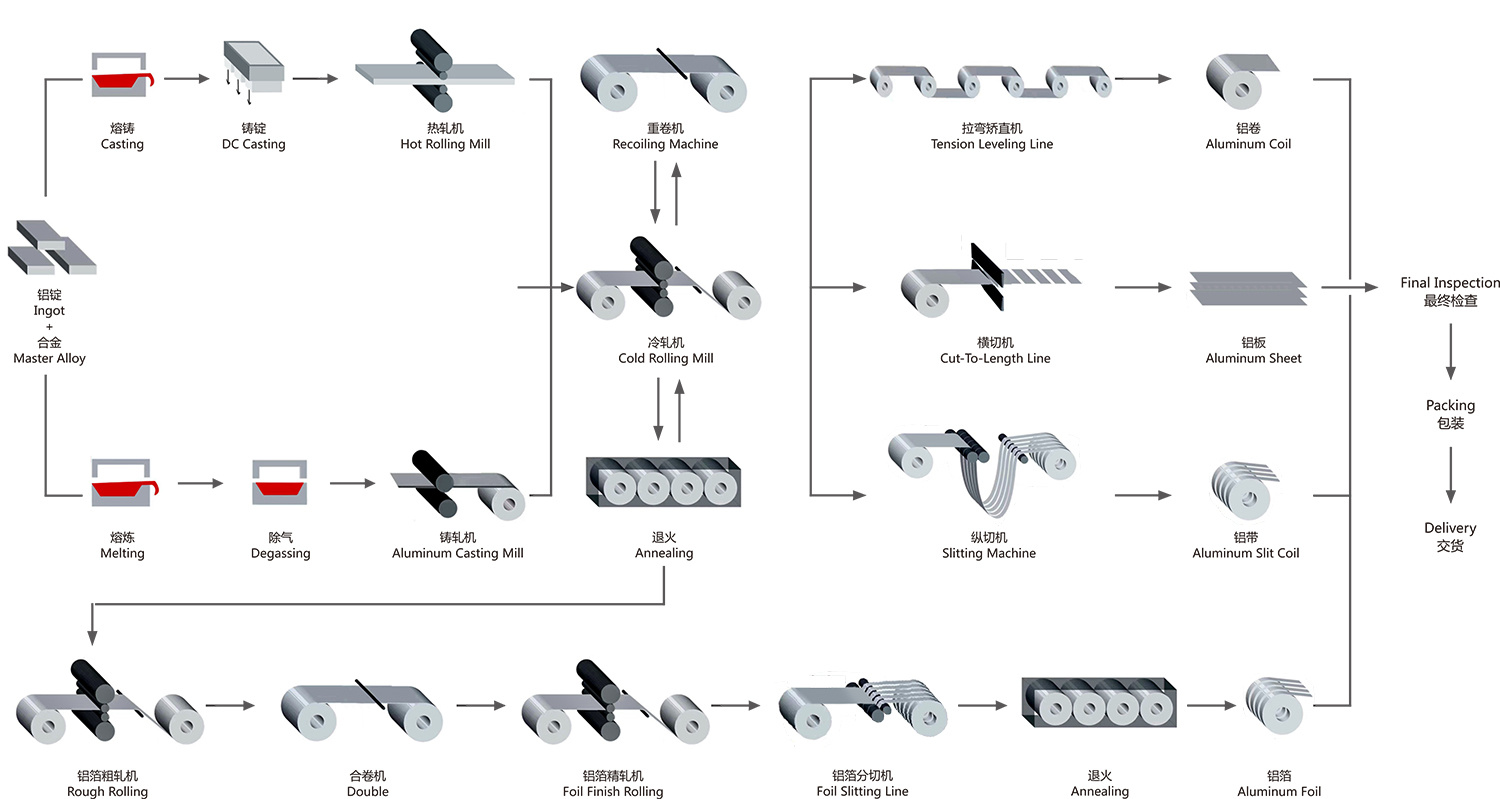

Process Flow

1.Melting Furnace

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

2.Holding Furnace

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

3.Degassing Unit

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Insulation method: electrical heating

Power:90-150 KW

4.Casting Rolling Mill

Finished product thickness: 5.0-10mm

Finished product width: 800 -2200mm,Recommended models on demand

Rolling speed: 800 - 5000mm/min

5.Cold Rolling Mill

Finished product thickness: 0.1-4.0mm

Finished product width: 950 -2250mm,Recommended models on demand

Rolling speed: Max 1500m/min

6.Tension Leveling Line

Finished product thickness: 0.1-4.0mm

Finished product width: 600 -2350mm,Recommended models on demand

Rolling speed: Max 80 - 600m/min

7.Annealing Furance

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:square, round

Customer Cases:

Henan Hengtong New Materials Co., Ltd

Guangxi Runtai Aluminum Co.,Ltd

Henan Xintai Aluminum Industry Co.,Ltd

Alukou Group