Case

Aliminium for Cable and Transformer Project

1. Transformer

Since the 21st century, with the rapid development of power electronics technology, transformers have been applied in more diverse scenarios, and the demands for their performance, cost, and size have become increasingly stringent. The application of aluminum foil in transformers has gained wider promotion:

In the field of inverter transformers, such as those used in high-power Uninterruptible Power Supplies (UPS), the market has largely shifted from copper to aluminum foil winding. This change has significantly reduced costs. At the same time, by improving processes, such as using ultrasonic welding technology, the problem of welding aluminum foil to aluminum or copper bars has been solved, enhancing production efficiency and product quality.

In some large power transformers, aluminum foil has also been used in special shielding or cooling structures to improve the electromagnetic compatibility and cooling performance of transformers.

In recent years, with the rapid development of fields such as renewable energy and rail transit, the demand for transformers has increased further, while higher requirements for miniaturization, lightweight, and efficiency have been raised. The application of aluminum foil in transformers has continued to innovate and evolve. For example, by developing new aluminum foil materials and processing techniques, the strength, conductivity, and heat resistance of aluminum foil are being enhanced to meet the needs of next-generation transformers.

2. Cable

Since the 21st century, the rapid development of information technology and electronic devices has diversified the types and uses of cables, leading to the broader application of aluminum foil in cables:

In high-speed data transmission cables, such as Ethernet cables and USB cables, aluminum foil shielding can effectively reduce external electromagnetic interference, ensuring the accuracy and stability of data transmission.

In power cables, aluminum foil is also used to reduce the electromagnetic field generated during cable operation, thus lowering electromagnetic pollution. It also helps prevent external electromagnetic fields from interfering with the internal power transmission of the cable.

With the growth of smart buildings and smart homes, the demand for various wires and cables has surged, and the requirements for cable shielding performance have become higher. Consequently, aluminum foil is increasingly being applied in these areas.

In recent years, with the rise of emerging fields such as 5G communication technology, the Internet of Things (IoT), and electric vehicles, higher performance requirements have been placed on cables. The application of aluminum foil in cables continues to evolve, with innovations such as the development of thinner, lighter aluminum foil with better shielding performance. Multilayer shielding structures (such as aluminum foil combined with other metal meshes) are also being adopted to enhance the anti-interference capability of cables. Additionally, to meet environmental sustainability goals, research is being conducted on recyclable and biodegradable aluminum foil cable materials.

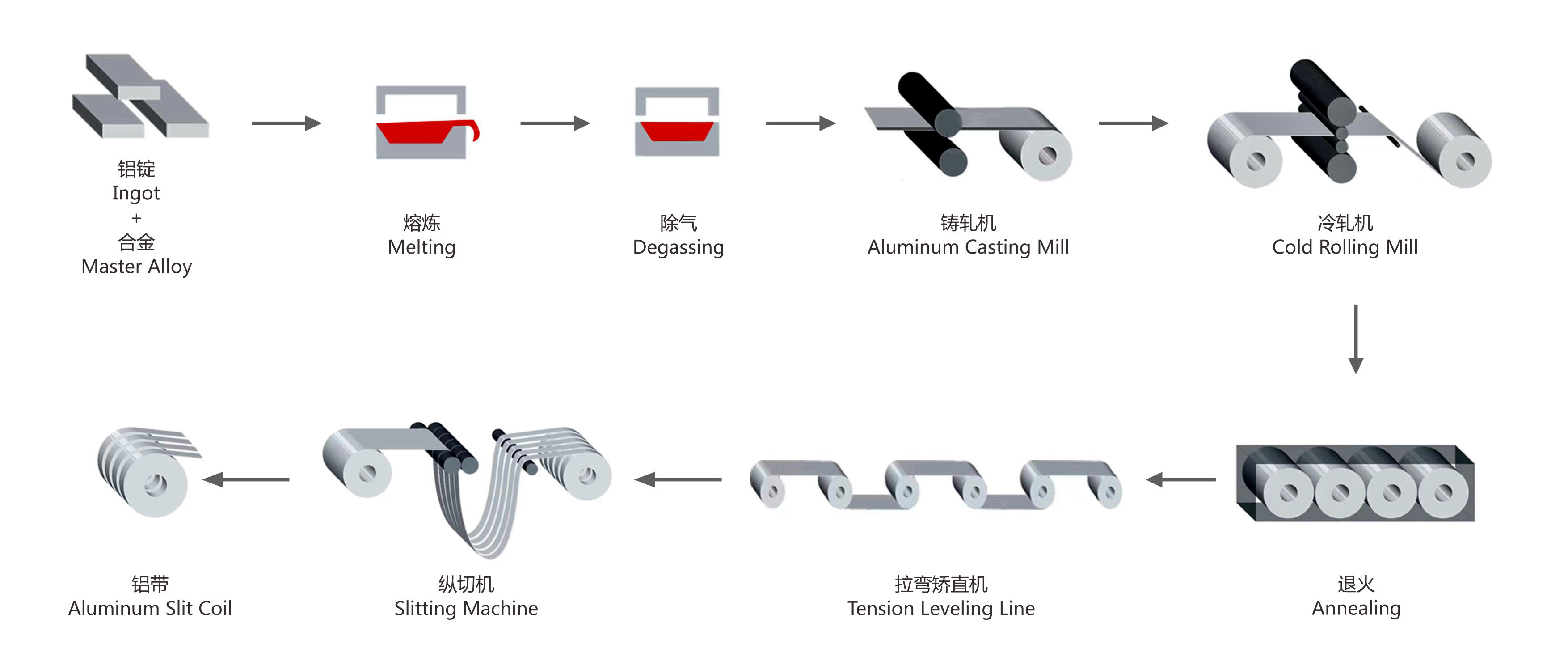

Process Flow

Product Structure

Application | Thickness | Usage | Width | Usage |

| Cable | 0.01 - 0.05 | In high-frequency signal transmission cables (such as Ethernet cables, USB cables, etc.), it can effectively shield against external electromagnetic interference, ensuring the accuracy and stability of data transmission. In power cables, it can reduce the electromagnetic field generated during cable operation, lowering electromagnetic pollution, while also preventing external electromagnetic fields from interfering with the internal power transmission of the cable. | 10 - 100 | Used in internal connection cables of small electronic devices, such as the data cables inside mobile phones and laptops. It can tightly wrap around the cable core, providing localized electromagnetic shielding and preventing interference between different signal lines. It can also be customized according to the design of cables with special shapes or structures, such as flexible cables. |

| 0.05 - 0.55 | In cables used in areas with strong electromagnetic interference (such as near large motors, inside high-voltage substations), it enhances shielding effectiveness. In long-distance signal transmission cables, it reduces signal attenuation during transmission. | 500 - 1600 | Used in the main cables of large data centers (such as the connection cables between large server cabinets), it can cover multiple cores at once, improving shielding efficiency and reducing signal interference. It is also used in special communication cables (such as the shielding layer outside the metal reinforcement core of multi-core optical cables) to provide comprehensive electromagnetic shielding, ensuring stable transmission of optical signals. | |

| Transformer | 0.08 - 0.5 | Commonly used in some small transformers. In the windings of small transformers, it meets basic electrical performance and heat dissipation requirements. | 20 - 100 | Suitable for the windings of small transformers, allowing for easy winding and installation in small spaces. |

| 0.5 - 3.0 | In large power transformers, it can be used in special shielding structures or heat dissipation structures to improve the electromagnetic compatibility and heat dissipation performance of transformers. It can also withstand higher electrical and mechanical stresses. | 100 - 1650 | Suitable for the windings of large transformers, meeting the requirements for current-carrying capacity and heat dissipation in large transformers. It can cover a larger area of the winding, reduce electromagnetic field leakage, and improve the overall performance of the transformer. |

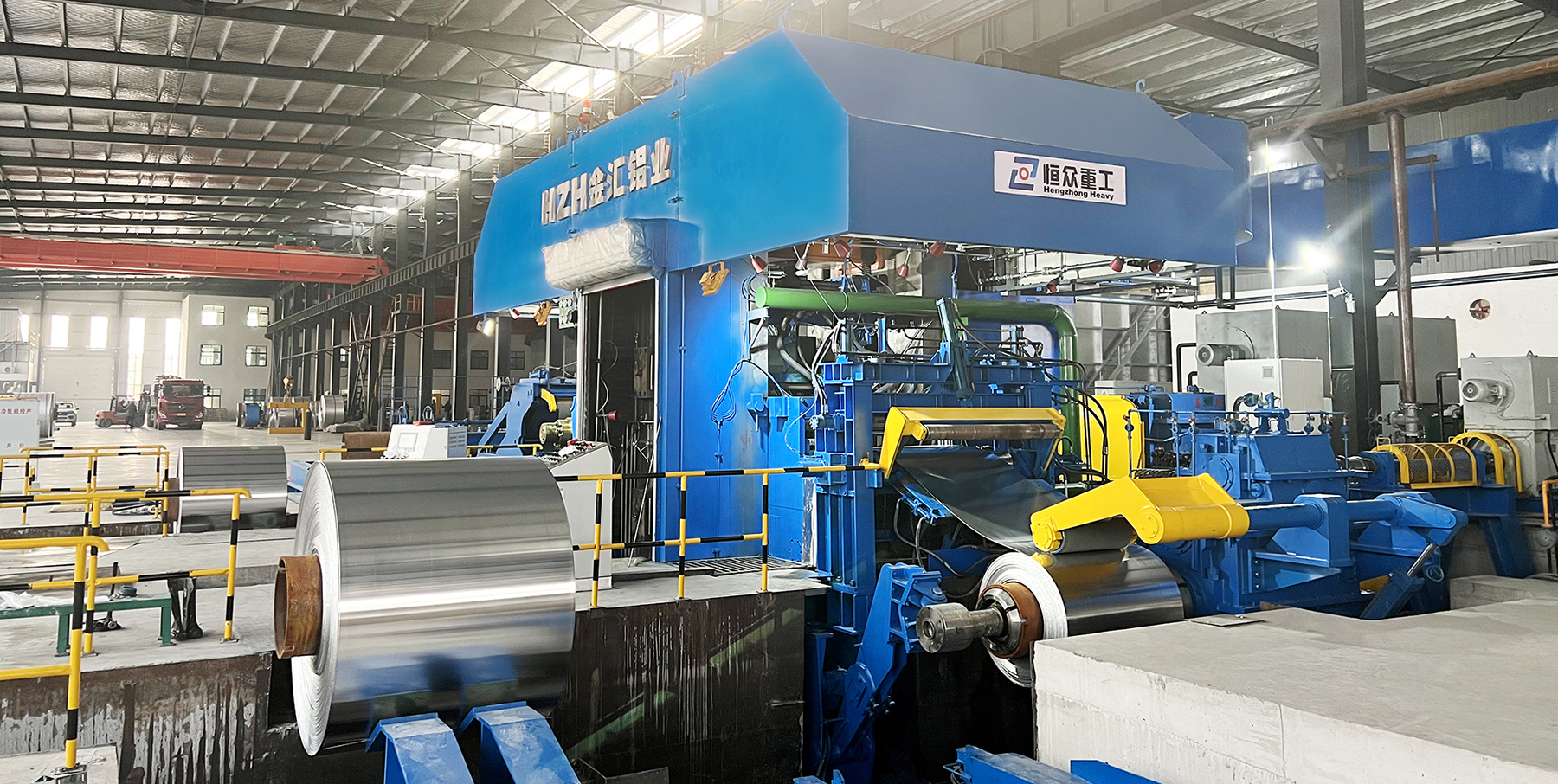

Main Equipment

1.Melting Furnace

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

2.Holding Furnace

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

3.Degassing Unit

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Insulation method: electrical heating

Power:90-150 KW

4.Casting Rolling Mill

Finished product thickness: 5.0-10mm

Finished product width: 800 -2200mm,Recommended models on demand

Rolling speed: 800 - 5000mm/min

5.Cold Rolling Mill

Finished product thickness: 0.1-4.0mm

Finished product width: 950 -2250mm,Recommended models on demand

Rolling speed: Max 1500m/min

6.Tension Leveling Line

Finished product thickness: 0.1-4.0mm

Finished product width: 600 -2350mm,Recommended models on demand

Rolling speed: Max 80 - 600m/min

7.Annealing Furance

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:square, round

8.Slitting Line

Finished product thickness: 0.2-1.5mm

Product width: 500-1250mm

Slitting Width: 15-1000mm/min

Number of slitting strips:6-40

Rolling speed: 0-200m/min

Customer Cases:

Henan Hengtong New Materials Co., Ltd

Guangxi Runtai Aluminum Co.,Ltd

Henan Xintai Aluminum Industry Co.,Ltd

Alukou Group