PRODUCTS

PRODUCTS

Further Information

Large Ring Gear

Category:

E-mail:

Whatsapp:

-

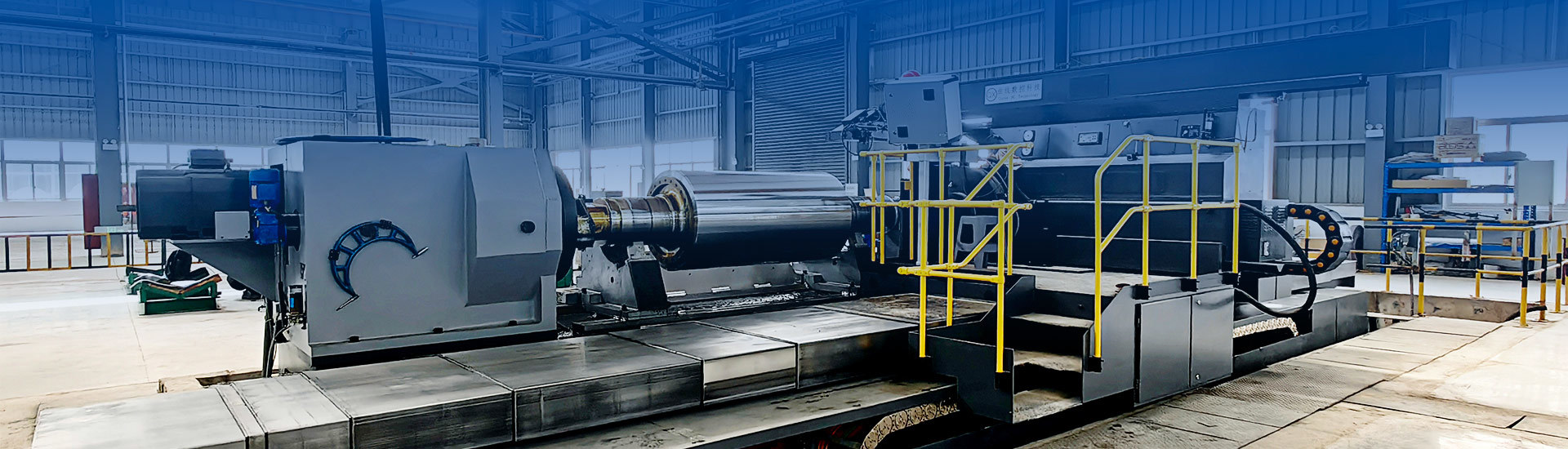

Our large girth gears are key transmission components widely used in rotary kilns, ball mills, rotary dryers, metallurgical furnaces, and other heavy-duty industrial equipment. Designed with high precision and manufactured using advanced casting, forging, and machining technology, our gears ensure stable transmission, long service life, and excellent load-bearing performance.

We supply customized girth gears with diameters up to 12 meters, meeting international standards (ISO, DIN, AGMA, GB) to serve cement plants, mining operations, steel mills, and power plants worldwide.

Technical Parameters (Customizable):

Parameter

Specification (Typical Range)

Gear Type Spur Gear / Helical Gear Module (M) 10 – 50 Tooth Surface Hardness HRC 45 – 60 (after heat treatment) Outer Diameter Up to 12,000 mm Material Options 42CrMo, 35SiMn, 45#, ductile cast iron Manufacturing Method Casting / Forging / Fabrication Accuracy Standard DIN 6 – 9 / AGMA 8 – 10 / ISO Grade Application Torque Up to 3,000,000 Nm

Material Options:

- 42CrMo / 40Cr: High strength, toughness, and wear resistance

- 35SiMn: Excellent impact resistance

- Cast Steel (ZG270-500,ZG45, ZG42CrMo): Common for large girth gears in rotary kilns

- Ductile Cast Iron: Cost-effective with good machinability

Applications:

- Rotary kilns (cement, metallurgy, lime)

- Ball mills and SAG mills (mining and mineral processing)

- Rotary dryers and coolers

- Metallurgical furnaces

- Large-scale transmission systems

Key Features:

- High-Strength Material: Alloy steel or ductile iron with excellent toughness and wear resistance

- Advanced Heat Treatment: Ensures surface hardness, wear resistance, and durability

- Precision Machining: High-accuracy gear tooth profile for stable and efficient transmission

- Custom Design: Available in different module, helix angle, pressure angle, and tooth width according to customer drawings

- Long Service Life: Optimized structure reduces stress concentration and improves fatigue resistance

Packaging & Delivery:

- Anti-rust coating and seaworthy packing (wooden case or steel frame)

- Delivery time: 45–90 days depending on gear size and order quantity

- Worldwide shipping available

Key words:

Previous Page:

Next Page