Case

Recycled Aluminium Casting Project

Introduction Of The Project

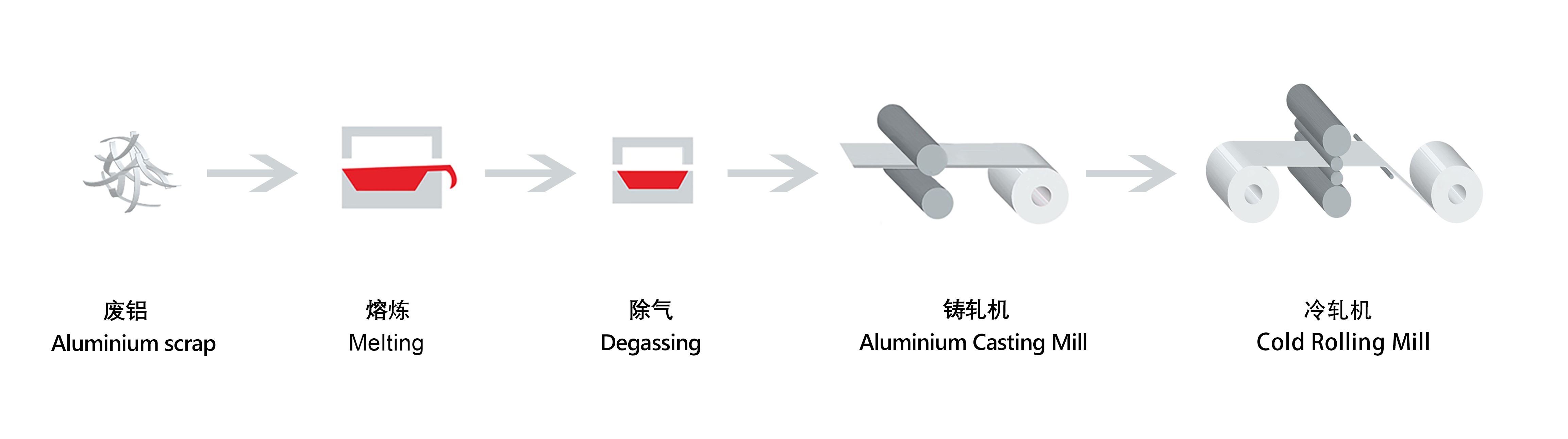

Among structural metals for industrial use, aluminum has the highest recyclability and the highest regeneration efficiency. Due to the high corrosion resistance of aluminum, except for some aluminum chemical containers and devices, aluminum products are basically not corroded during their use, and almost all can be recycled. In the other hand, the actual production energy consumption of secondary aluminum does not exceed 5% of the energy consumption of electrolytic aluminum. Therefore, recycling and regeneration of waste aluminum is an energy-saving project with huge benefits. China is one of the largest aluminum producers and consumers in the world, but due to the constraints of energy conservation, emission reduction, resource shortage and other factors, its development has also fallen into a hard time. Because of its environmental protection, recycled aluminum has attracted more and more people's attention.

The main raw materials for melting recycled aluminum are industrially depreciated aluminum scrap parts (such as scrap parts of aircraft and engines, casing covers, etc.) and aluminum scrap produced during aluminum processing (including waste wire, plates, tubes, bars, profiles, debris, Foil, etc.).

Processing Flow

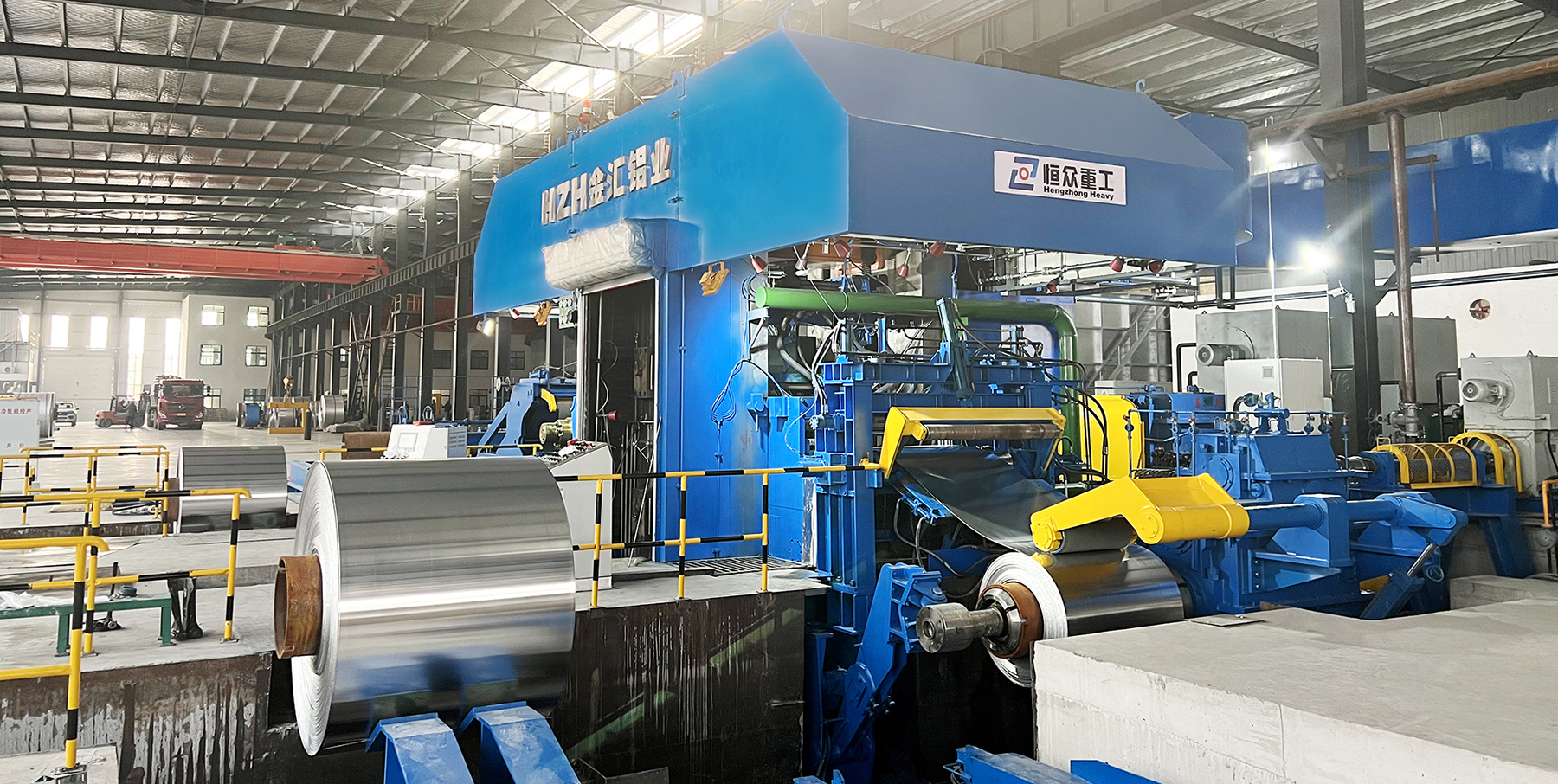

Main Equipment

1.Melting Furnace

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

2.Holding Furnace

Energy: electricity, natural gas

Size: 5 tons, 10 tons, 20 tons, 30 tons, can be customized

Shape:round, square

3.Casting Rolling Mill

Finished product thickness: 5.0-10mm

Finished product width: 800 -2200mm,Recommended models on demand

Rolling speed: 800 - 5000mm/min

4.Cold Rolling Mill

Finished product thickness: 0.1-4.0mm

Finished product width: 950 -2250mm,Recommended models on demand

Rolling speed: Max 1500m/min